|

SCALE MODELS & COLLECTIBLES

|

||

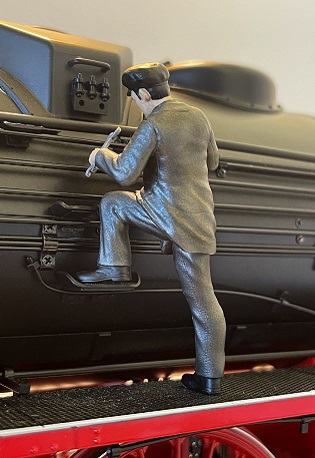

3D Design, Reverse Engineering Development, OEM ProductsSpringlight is originally specialized in the publishing field of Partworks collections and series. In this field, not only has Springlight been sourcing many types of products but also learned how to combine and integrate diverse competencies among a same series, as well as techniques and even technologies to come up with very innovative solutions. From static models, mechanical and electronic parts were included, and more recently, it has become robotized with advanced functionalities (programming, walking abilities, telepresence, app control, cloud service ...). The critical success factor has been bringing these advanced features at very competitive costs. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Those competencies in manufacturing OEM products can be transposed to any other fields requiring breakthrough ideas to create innovative products and a more excellent value to the end-users. |

|

|

As an edvidence of quality and social responsibility, our manufacturing partners are also FAMA Certified. Either through our Chinese partners or in our Tunisian workshop, we have the capacity to produce and decorate PVC figurines. |

|

|

|

|

|

|

In other words, Springlight will bring you breakthough creativity and innovative products, and the benefits of a unique competitive advantage for your logitics closer to Europe and Sustainability goals.

|

||

|

CHILDREN'S BOOKS

|

||

Know-How and Expertise from ThailandWith a strong background in the book publishing industry, Springlight has set up a line to produce Children's Books in Tunisia. In order to guarantee the quality, a Thai-Partner has transfered its know-how and valuable expertise for the Hand-Assembly Process. |

||

|

|

|

Combined-Manufacturing with ChinaTo keep the benefits of being close to Europe, Springlight has built an hybrid logistic model, combining supplying paper and manufacturing of the electronic components from China. Concretely: shipping chips blank from China, program loading is performed in Tunisia. Production lead time of the books can be divided by half, with additional savings on your shipping costs. |

|

Your benefits: |

||

|

OUR GOALS FOR SUSTAINABILITY

& SOCIAL RESPONSIBILITY |

||

|

GHG (Green House Gas) emission is part of Sustainability which is a scope Springlight pays very much attention to. Concretely, in order to differentiate itself providing higher value to clients, not only has Springlight obtained the ISO 9001 Certification to ensure a qualitative management of its services but also the ISO 14001 to embrass Sustainability. |

|

Springlight has been awarded 2 years in row BRONZE MEDAL

as a recognition of its Ecovadis rating, |

Recycling, Carbon Footprint, SPOPE 3 ...The first concrete action has been designing eco-responsible packaging with its customers. True that by the time COVID19, disposable plastics were in all packaging. Now, you will see brown corrugated boxes instead, and when opening up brown paper envelopes. Though recyclable plastic materials remain for only minimal parts, if any, they will soon be replaced by adapted paper materials. The 2nd action for Springlight is to calculate its Corporate Carbon Footprint (CCF) by proceeding with a greenhouse gas inventory (GHG inventory) of its value chain under SCOPE 1, 2, and 3. Performing this inventory will contribute at a larger scale to redesigning the supply chain. Indeed, to be disruptive enough to tackle the increase in GHG emissions, Springlight is setting up production means closer to Europe, where its primary customers are. Shortening the supply chains will directly reduce your carbon footprint, ... as well as other emissions of GHG, to respond better to the challenges of sustainability. Circular EconomyLastly, Springlight's products target grownups and collectors. The buildup models are often the "work of a lifetime" for their owners, meaning Springlight's products are designed and made to last. For those with mechanical or electronic functionalities, they can be repaired. As for other aspects of the Circular Economy, though concrete subject still needs to be addressed, Springlight remains attentive to the clients' requests |

Zero-Plastic & Recycling |

Reducing CO2-eq |

Circular-Economy Goals |

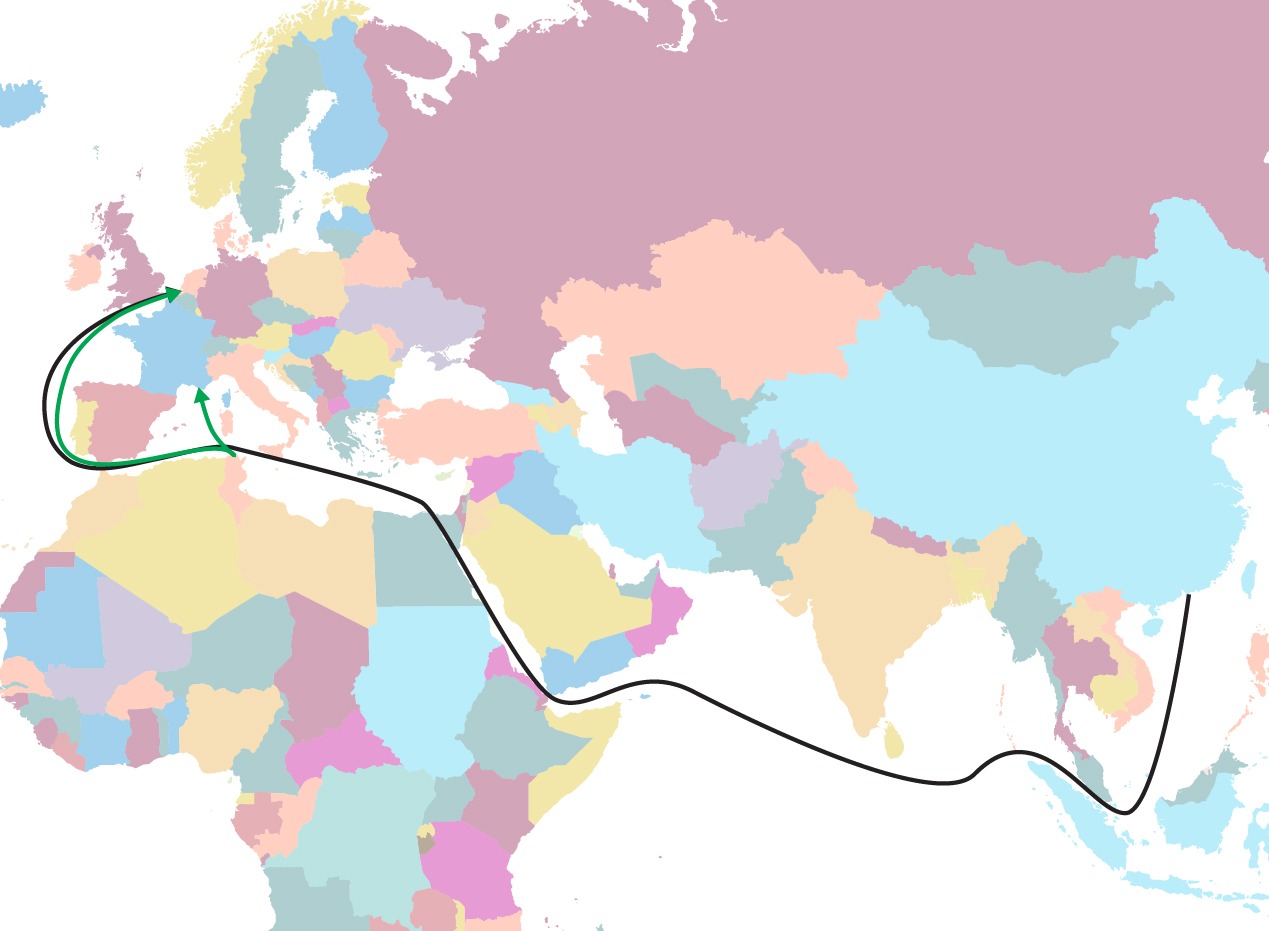

Green Vessels: use CO2-eq metric measureWe shall keep ourselves rational and practical ... When hearing about "Green cargo ships" fueled with LNG (Liquid Natural Gas), it often comes along with "Methane makes no carbon emissions". However, that solution brings you only marginal improvements in terms of GHG. First, LNG vessels count today for less than 5% of the total fleet, and by 2030 a maximum of 20% when all current orders will be sailing. Therefore, your containers have little chance of boarding an LNG vessel. Then, though it's true that CO2 emissions are reduced when using LNG-fueled vessels, methane is very much troublesome to handle at extraction, production, and logistics stages, creating many leakages directly into the atmosphere. Knowing that methane's GWP (Global-Warming Potential) is more than 80x greater the one of CO2 at 20 years (GWP20), it means you must consider the metric measure CO2-eq (CO2 equivalent) instead of considering CO2 only. You will then see that the gain in reduction is hardly 10 to 20% compared to regular vessels using CMO (Common Marine Oil). Quantified Comparison with CO2-eqThis is why Springlight's goal is now to set up hybrid logistics schemes with production in the Far East and a thousand km away from Europe only. That's the most effective way to drastically reduce emissions while shipping your goods by sea. Data says: the emissions per TEU (Twenty-foot Equivalent Unit) from HKG to Europe are about 1mT of CO2 when the emissions for the same container from Maghreb will only be 100kg. If you consider an LNG vessel, the reduction in CO2-eq will be ~150kg out of the 1000kg. Still it will remain (1000-150)/100 = 8.5x greater per TEU than from Maghreb. The above comparison is based on the Westbound route through the Red Sea and Suez Canal. However, recent political tensions in that region reroute the vessels by the Cape of Good Hope. The distance becomes another 20% longer. So is the GHG emission. |

|

|

|

Manufacturing GHG InventoryAfter obtaining the electricity consumption in kWh from its factories, Springlight now knows better where the masses are. In fact, it's important to reduce the emissions generated by the shipping leg, however, manufacturing is the major cause of CO2-eq within its value-chain. Another positive finding shows that depending on the countries' fuel used for their power plants, the GHG emission reductions can go down by 20% (ie. producing electricity in China => 550g CO2-eq/kWh vs. Tunisia with 446g CO2-eq/kWh only source: nowtricity.com). It also depends on how much low-consumption efficient factories' equipments are. All this work helps elaborating improving solutions throughout all steps of the supply chains. A Mix of Manufacturing OriginsThe solution is therefore to implement a virtuous breakdown between the Far East mastering many techniques and skills at higher international standards, and new origins closer to the markets where goods are commercialized. All depends on the complexity of products to manufacture. Assuming a mix of origins at 50/50, we can expect reducing emissions on shipping by 40%, and another 10% on manufacturing when coming closer to destination markets. This would make Springlight saving 80mT of CO2-eq annually based on 2022 activity level. A Reliable Partner to Achieve Your Sustainability GoalsIn other words, not only will Springlight develop and manufacture your products with added value for end-users, but it will also contribute to turning your business towards a more sustainable future, fulfilling the EU's CSDD and CSRD, or the US EPA, or any other governmental regulations and directives. |

|

OUR TEAM

|

|||||

|

With a background in engineering, Eric has also been able to follow and keep himself up-to-date with the changes in technologies. After two years of the pandemic, geopolitical changes with trade tariffs, and environmental challenges, Eric is reorganizing Springlight's supply chain focusing on new zones for manufacturing, and sustainability with reduction in CO2 emissions and GHG. |

|||||

|

|||||

|

OUR ORGANIZATION

|

|||||

|

Management & Sales Services:  15 SCOTTS #05-10 15 Scotts Road 228218 SINGAPORE e-mail: info@springlight.sg Office: +65.69808278 UEN 201843042G Tunisia Manufacturing Facilities:  Springlight Fabrication Suarl |

|||||

©Springlight EcoProd Pte. Ltd. 2025, all rights reserved. |

Jasmine worked in Japanese companies as Production Controller and Senior Merchandiser for many years. She knows about manufacturing processes and the production cycle, from the initial product development to the goods delivered to the end users. Her latest responsibilities were at one of the biggest Japanese retail companies that required strict control of quality, scheduling, and cost negotiations. Jasmine had excelled in this position in both Japan and then Singapore.

Jasmine worked in Japanese companies as Production Controller and Senior Merchandiser for many years. She knows about manufacturing processes and the production cycle, from the initial product development to the goods delivered to the end users. Her latest responsibilities were at one of the biggest Japanese retail companies that required strict control of quality, scheduling, and cost negotiations. Jasmine had excelled in this position in both Japan and then Singapore. Ahmed, Production & Logistics Manager. After obtaining his Master's Degree in Mechanical Engineering at the ENSIT (Ecole nationale superieur d'ingenieur de Tunis), Ahmed joined a major cardboard maker. There, in charge of the production, Ahmed managed quality, costs and schedule.

Ahmed, Production & Logistics Manager. After obtaining his Master's Degree in Mechanical Engineering at the ENSIT (Ecole nationale superieur d'ingenieur de Tunis), Ahmed joined a major cardboard maker. There, in charge of the production, Ahmed managed quality, costs and schedule.